Contents:

A Lathe Machine is one of the most important material removal methods in the technology of manufacturing. It is basically a collection of material-working processes that involve other processes. A lathe is a machine tool used principally for shaping pieces of metal and wood or other materials by causing the work piece to be held and turned by the lathe while a tool bit is advanced into the work on the cutting function. A powerful machine that is useful to shape wood in machining is the lathe machine.

Types of Lathe Machine and Its Operations

Lathe machines are commonly used in metalworking, metal spinning, wooding and glazing. Lathe machine includes actions such as sand, cutting, kneeling, drilling, and distortion of the tools employed to create symmetrical substances about sand axes. Some of the most common types of the lathe machine:

Light Duty Lathe Machine

Medium Duty Lathe Machine

Heavy Duty Lathe Machine

All Gear Lathe Machine

CNC Lathe Machine

Vertical Turning Lathes

Turning Lathes

Heavy Duty CNC Lathe Machine

Gear Head Lathe Machine

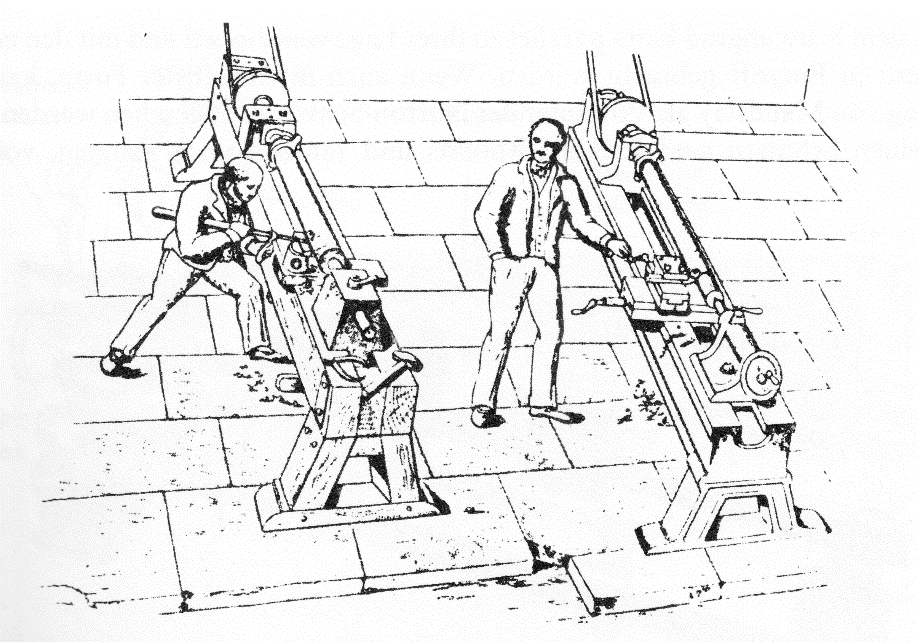

History of Lathe Machine

A lathe is an ancient tool, with Weak evidence for its survivor at a Mycenaean Greek site, dating back as far as the 13th or 14th century BC.

The lathe was very important to the Industrial radiancy. It is known as the mother of machine tools in industries, as it was the first machine tool that signs to the invention of other machine tools. The first fully equipped, all-metal slide rest lathe was invented by Jacques de Vaucanson around 1751.

Parts of a Standard Wood Lathe Machine

Headstock The headstock contains the high precision bearings which hold the horizontal axle, more commonly known as the spindle.

Spindle This is a hollow horizontal axle with interior and exterior threads on the inboard by which the woodworking pieces can be mounted on.

Bed This is usually a horizontal beam that holds the chips and the swarfs.

Tool Rest A horizontal area in line with the spindle and the tailstock from which hand tools are to control it and lever into the work pieces.

Lock Knob Sits on top of the cross-slide and holds the cutting tool in place.

Tailstock Sits on top of the cross-slide and holds the cutting tool in place.