Contents:

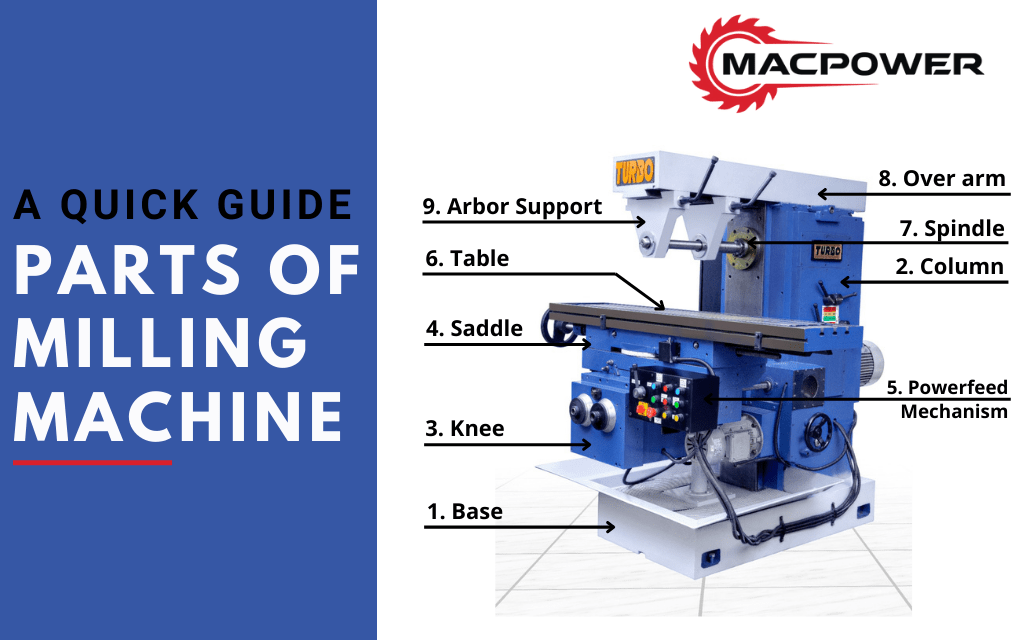

Parts of a Milling Machine: A Quick Guide

In today’s post, I’m going to show you exactly what are the fundamental parts of the milling machine.

In fact:

These are the same parts that we used to build our high-quality milling machine. After you read this post, you’ll have all the information you want to know about lathe machine parts. So, let’s dive right in.

Milling Machine Parts

Since each type of milling machine comes with its design and features, some of the machine parts will vary between different machines. Here is the list of major parts, you will find in any milling machine.

- Base

- Column

- Knee

- Saddle

- Power Feed mechanism

- Table

- Spindle

- Overhanging Arm

- Arbor Support

Base

The base is the foundation part of the milling machine. It bears the weight of all other parts. It is made from grey cast iron. There is a good reason behind it. You see, when you perform any kind of machining operation on a milling machine, it will generate lots of vibration, and grey cast iron has a high damping capacity.

The inner portion of the base is hollow, it is used as a coolant reservoir.

Column

A Column, as it sounds, is a tall column mounted vertically on the rear side of the base. And just like the base, it also is made from grey cast iron for the same reason.

The column comes with a hollow structure, inside it driving mechanism, and motor are fitted. On the other hand, other major parts such as the spindle, overarm, and knee are mounted on the outside.

Knee

The knee is mounted on the front side of the column and can slide up and down along the slideways built over the column.

The main function of the knee is to adjust the distance between the milling cutter and workpiece. It is driven by either a mechanical or hydraulic mechanism.

You will also find an elevating screw jointed along with the knee. It is used to adjust the height of the knee.

Saddle

The saddle is located between the knee and the work table. It is used to move the workpiece in a horizontal direction.

Power Feed mechanism

The power feed mechanism is a set of mechanisms situated inside the knee and used to control the longitudinal, transverse, and vertical feeds.

In other words:

This mechanism enables you to move your workpiece in the left-right, in-out, and up and down directions.

You can also set the feed rate of the machine, by using the feel selection lever located on the front side of the control panel.

Table

Table, as the name suggests, is a worktable located above the saddle. It gives you the facility to hold the workpiece during the milling operation.

It has a few t-slots on it so that you can fit clamping devices to hold your job or other work holding devices such as jigs and fixtures.

Spindle

A spindle is a rotating shaft that holds your cutting tool or arbor. The primary purpose of the spindle is to support your cutting tool and provide a rotary drive so that it can remove the material from the workpiece.

The rear end of the spindle is connected with the electric motor, and the front is used to hold the cutting tool or arbor.

Overhanging Arm

An overhanging arm is a horizontal structure and is located is on the top face of the column. It is usually made from a single cast-iron structure and, it slides on the dovetail way which is fitted the top surface of the column.

The overarm is used to reinforce the Arbor.

Arbor Support

Arbor support is a casting structure––located below the outer end of the overhanging arm.

The primary function of the Arbor is to give support to the outer end of the Arbor, so it stays in the alignment and does not wiggle during the cutting operation.

Conclusion

Okay, so that was all the information that you might want to know about parts of the milling machine.

I hope you like it. Feel free to share this post… and… if you have any questions related to milling machine parts you can ask us simply by filling out the contact us form.

See you in the next post.